How to Make a Pineapple: FINE’s First Adventure In 3D Printing

Posted in Insights

At FINE, we make stuff. Creative folks are like that. So we are especially intrigued by the idea of being able to make physical stuff from digital stuff using the newfangled 3D printing technology. This past week we decided to try it. Turns out your computer can’t make an edible jelly doughnut and cup of tea materialize on request like in Star Trek, but still, 3D printing stuff is pretty easy and tons of fun.

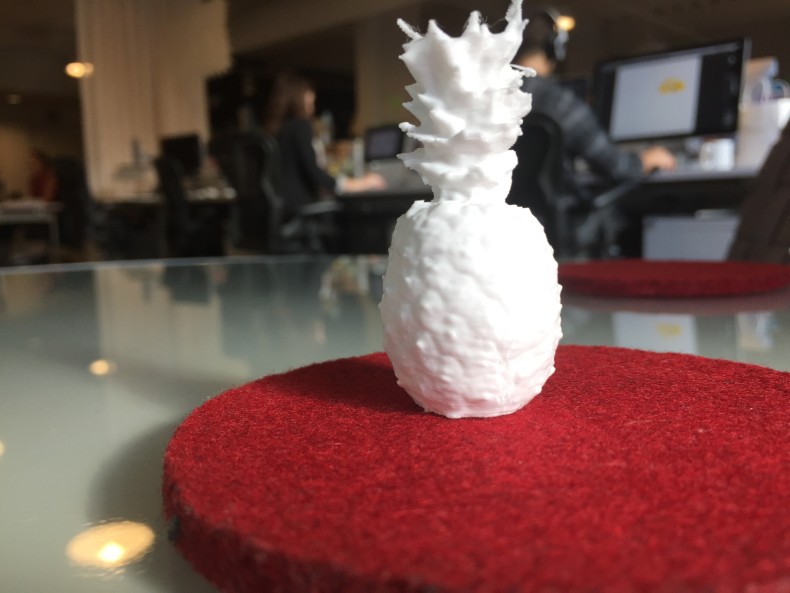

The first thing we needed was a 3D printer. Luckily for us, one of our staff was willing to share their Dremel Idea Builder, a Fused Filament Fabrication (FFF) style printer that basically works like a glue gun mounted on a two dimensional moving print head with a print table that moves up and down. Put simply, it melts tiny bits of plastic from a spool and builds up your “thing” one slice at a time.

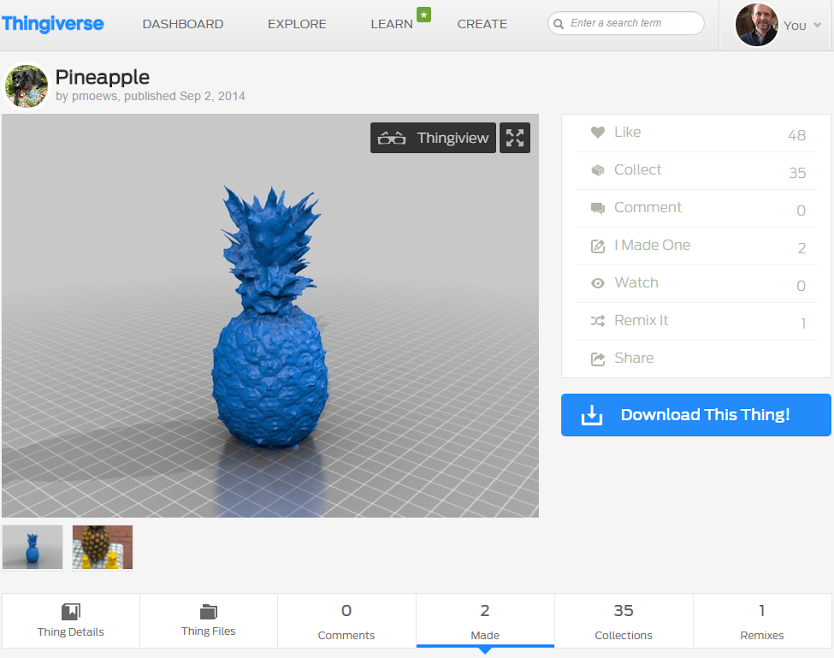

Now we needed something to print. Since this is an exercise in printing something, not concepting something, we turned to the trusty Internet and used a site called Thingiverse.com to locate a 3D model of a pineapple. Why a pineapple? First, because Emily here at FINE is a bit obsessed with them. But mostly, why NOT a pineapple?

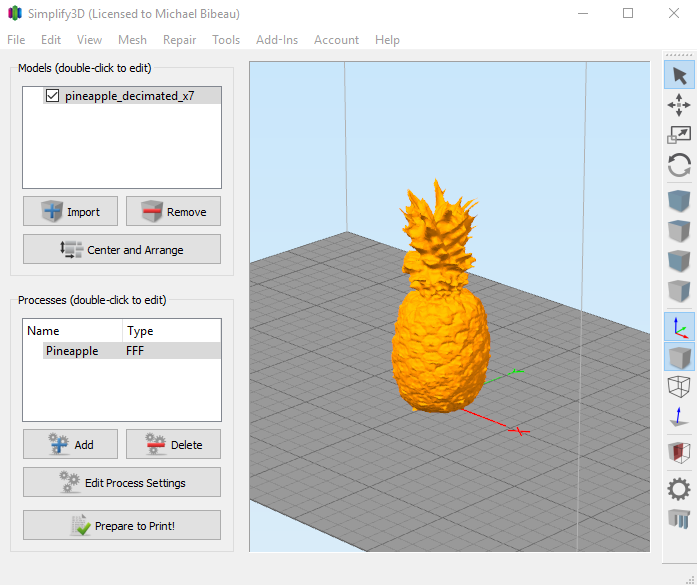

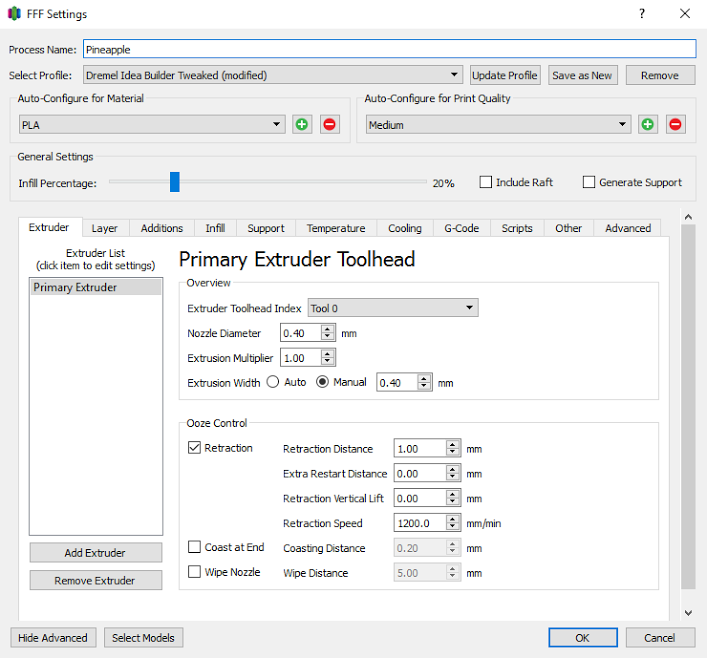

We downloaded something called an .STL file (for “stereolithography”) which describes a 3D model in a sort of universal language. Using that language, any of the several flavors of 3D printer can then turn that file into a physical object build description, just like your laser printer or inkjet printer can both print the same document. So we next needed to get that file into a format that our particular 3D printer can understand. We used a non printer-specific program called Simplify 3D to translate the .STL into a printable description for our Dremel printer using the desired print quality and other customizable settings.

[slider]

[slide]

[/slide]

[slide]

[/slide]

[slide]

[/slide]

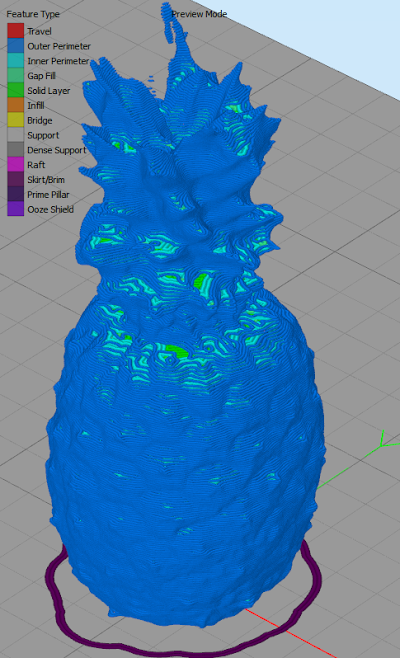

[/slider]What we ended up with is a print-head description file that tells our printer exactly how to move around, what temperature to be, how much plastic to use and a myriad of other instructions. Yes, 3D printing is not quite to the level of simplicity as your laser printer yet, but remember that back in the day, laser printers required quite a bit of TLC to print complicated graphics and large documents. Give it time and folks like us experimenting to help the industry figure out all the best techniques to make it as simple as printing a document is today.

Now that we had our 3D object translated into a “toolpath definition” format that the physical world can understand in terms of spitting melted plastic out of super-hot (220℃) 1.75mm nozzle at about .2mm thickness per layer, we transferred that file into the printer via a memory card and off we went.

And...voila!...

Someday, the melted plastic will be replaced by molecular reconstruction and we’ll be able to eat the pineapple. We’ll be printing pineapples all day long. We’ll be inventing new fruit hybrids, like the Mangorange or the Bananapple. Heck, we’ll be 3D-generating our own homes, spouses, planets, and missing sock matches. But for now, it sure was fun to simply make a physical thing materialize before our eyes.

![[]](https://media.giphy.com/media/xT0BKLyda3O1h7uixq/giphy.gif)